TPM objective Việt Quality

(PDF) EMC Consulting technical trainings · TPM Structure TPM

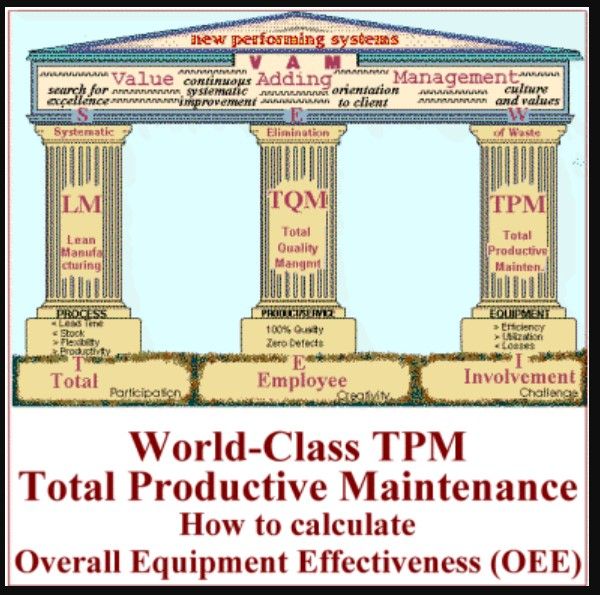

Total Productive Maintenance (TPM) is a maintenance strategy that aims to optimize the productivity and efficiency of manufacturing systems by involving all employees in the maintenance process. It is based on the principles of continuous improvement, preventative maintenance, and the involvement of all employees in equipment maintenance.

PPT Total Productive Maintenance ( TPM) PowerPoint Presentation, free

What are the Objectives of TPM? Objective 1: Boosting productivity and decreasing breakdowns to improve equipment performance. Objective 2: Encouraging participation from all staff members in the maintenance and improvement of the equipment, including operators and maintenance personnel.

Study of Manufacturing System Total productive maintenance (TPM

Total productive maintenance is comprised of three things:.

PPT History of Total Productive Maintenance (TPM) ADDVALUE Nilesh

Total productive maintenance ( TPM) started as a method of physical asset management, focused on maintaining and improving manufacturing machinery in order to reduce the operating cost to an organization.

What Is TPM (Total Productive Maintenance) in the apparel industry?

The objectives of total productive maintenance are as follows- Minimize cost Equipment reliability Reduce accidents Increased ownership amongst the employees Sharing of experience and knowledge Achieving goals Optimized work schedules of every employee Efficient workforce Avoid wastage Enhanced employee skills

TPM Guidebook CMM Introduction TPM Toolbox

The goal is to hold emergency and unscheduled maintenance to a minimum. Why TPM ? TPM was introduced to achieve the following objectives. The important ones are listed below. Avoid wastage in a quickly changing economic environment. Producing goods without reducing product quality. Reduce cost.

TPM. DR. K. BARANIDHARAN

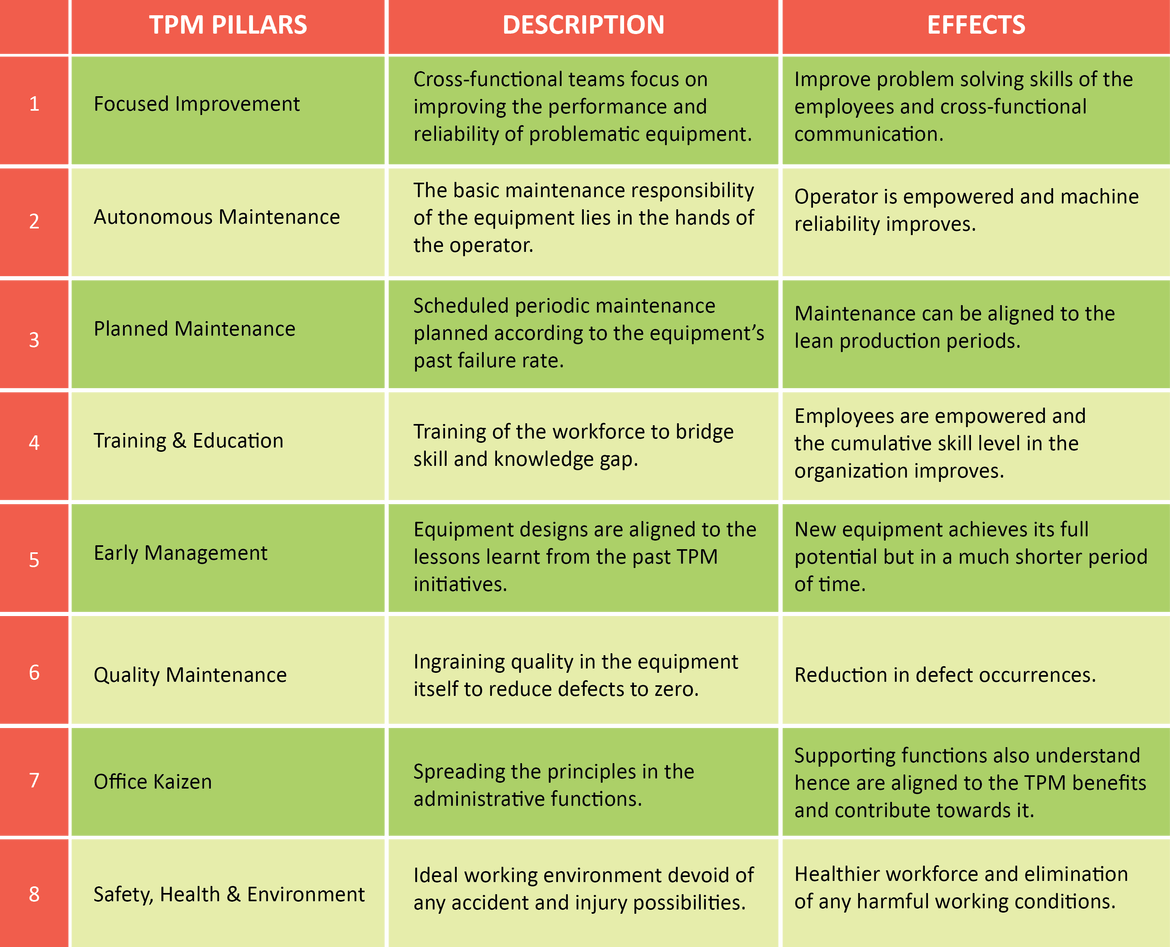

Objectives of TPM Benefits of TPM for your company The 8 Pillars of TPM 1. Autonomous maintenance 2. Focused Improvement (Kobetsu Kaizen) 3. Planned maintenance 4. Quality maintenance 5. Early equipment management 6. Administrative & office TPM 7. Education and training 8. Safety, Health, Environment TPM implementation phases

PPT Total Productive Maintenance (TPM) PowerPoint Presentation, free

Total Productive Maintenance is one of the lean management methods as a way to keep a greater effectiveness of the machines and devices and at the same. time ensure the access to critical devices. Find out more about the TPM, the TPM goals, pillars and big losses. Find out about the benefits of implementing.

TPM Team Guide How to Start & Sustain TPM Team Activities (149slide

Objectives of TPM Benefits of TPM for your company The 8 Pillars of TPM 1. Autonomous maintenance 2. Focused Improvement (Kobetsu Kaizen) 3. Planned maintenance 4. Quality maintenance 5. Early equipment management 6. Administrative & office TPM 7. Education and training 8. Safety, Health, Environment TPM implementation phases

OEE Total Productive Maintenance Objectives TPM Tool

Total productive maintenance (TPM) is a method used to boost the company's production, equipment efficiency by minimizing downtime. By implementing the TPM strategy, it's possible to see maintenance costs drop 25-30% and conversion costs decline by 20-25% over five years.

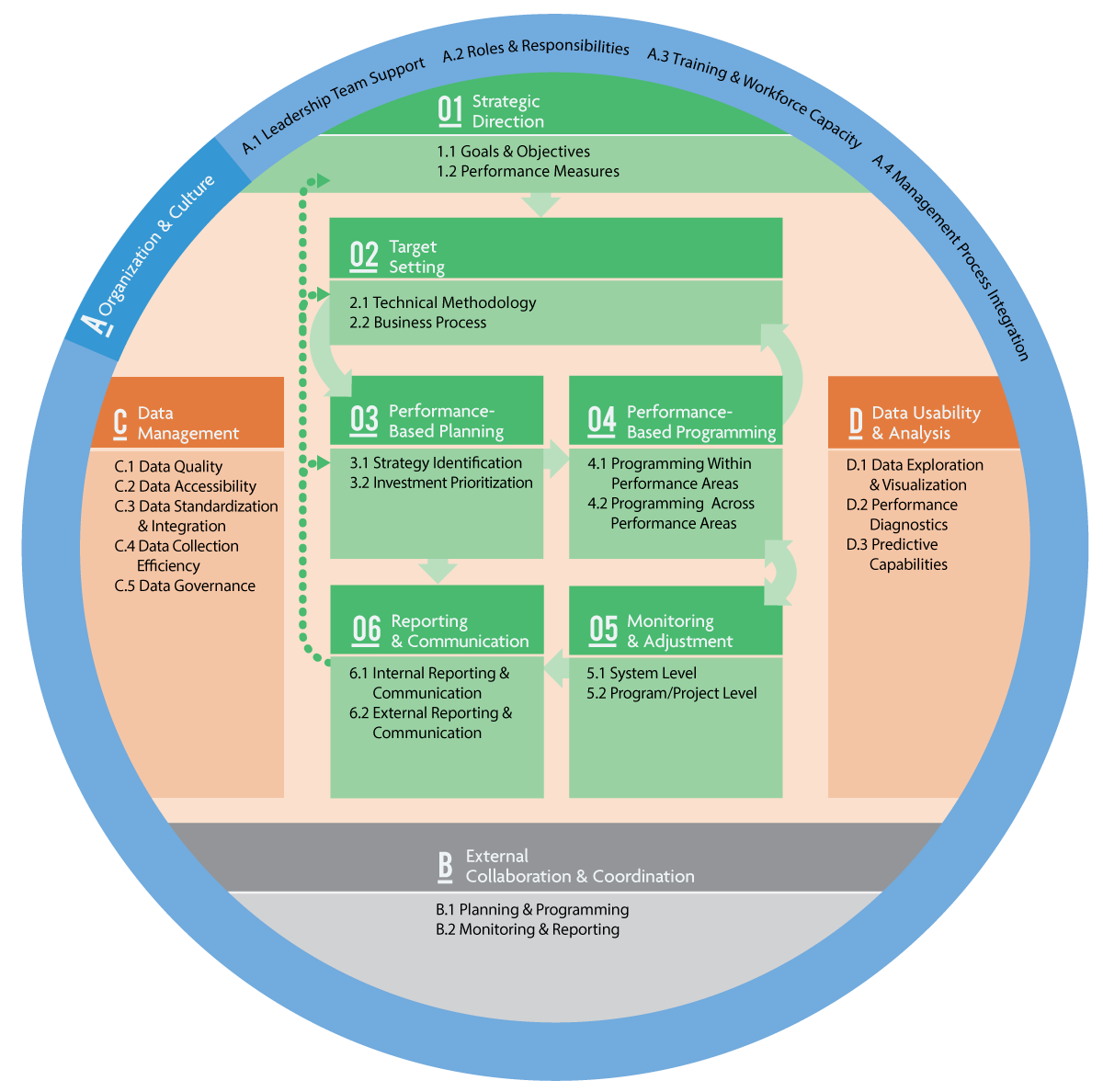

The Seven Boxes in the TPM Process Transformation Prayer

The Total Productive Maintenance (TPM) approach is " I OPERATE, and I FIX/MAINTAIN" i.e. the operators maintain their own machines and equipment condition proactively to enhance productivity and lower costs.. TPM is a culture that focuses on maximizing the OEE-overall equipment effectiveness (effectiveness of the plant, equipment, and processes) by involving all employees from top.

En Introduction To TPM Objectives and Benefits PDF

Objectives of TPM. The objectives of Total Productive Maintenance (TPM) are critical to achieving efficiency and success in manufacturing operations. Here's a breakdown of the objectives: 1. Maximize equipment effectiveness: TPM aims to ensure that all equipment is operating at peak efficiency, reducing downtime and increasing productivity.

What are the objectives of TPM? Creative Safety Supply

The Total Productive Maintenance (TPM) concept is one of the tools to maximize equipment efficiency by establishing an optimal relationship between people and machines.. The main objectives of TPM are: increasing the Overall Equipment Effectiveness ratio (OEE), increasing the productivity of the crew, achieving a zero defect rate.

Module TPM Lean Six · PDF fileAims & Objectives • Target Audience

The main objective of Total Productive Maintenance is to achieve almost perfect production, that is, to create a highly productive environment in which failures, accidents, downtime, slowdowns and waste are completely absent or, at least, reduced to a minimum. TPM achieves this goal through the development of some operational strategies, which.

Tpm Process Map Pic Transformation Prayer Ministry Vrogue

A key component of Lean Management/Manufacturing, total productive maintenance embraces a comprehensive strategy for optimizing facility maintenance with the primary goal of eliminating resource waste, employee accidents, product defects, and unplanned downtime.

Defining SMART PMO Objectives SMART Objectives Template

First: what is Total Productive Maintenance or TPM? TPM is a lean manufacturing philosophy that centres on achieving near-perfect production. The aims of TPM are high: no breakdowns, no small stops or slow running, no defects, and no accidents.